410A Pressures on a 95 Degree Day (Guide) In 2025

When it comes to HVAC systems, especially those using R-410A refrigerant, understanding pressure readings is crucial for proper system performance.

410A Pressures on a 95 Degree Day, One key question that many HVAC technicians, contractors, and DIYers have is: What are the typical pressures for R-410A on a 95-degree day?

In this article, we’ll break down what pressures you should expect on a hot day, how to troubleshoot common issues related to refrigerant pressure, and how to ensure your system is running efficiently during peak heat.

What Is R-410A Refrigerant?

Before diving into the specifics of 410A pressures, it’s essential to know what R-410A is and why it’s so commonly used in modern HVAC systems.

R-410A, also known as Puron, is a hydrofluorocarbon (HFC) refrigerant. It was developed as a replacement for R-22 refrigerant, which is being phased out due to environmental concerns.

R-410A has better efficiency and is more environmentally friendly than R-22, but it operates at higher pressures, which means understanding these pressures is even more important for troubleshooting and maintenance.

Why R-410A Is Preferred Over R-22

- Higher Efficiency: R-410A operates at higher pressures, making it more efficient at transferring heat.

- Environmental Friendliness: It has zero ozone depletion potential, unlike R-22, which harms the ozone layer.

- Performance: It can work more efficiently at higher temperatures, making it ideal for hotter climates.

Now that we know a little about R-410A, let’s dive into the pressures you should expect when using this refrigerant in hot weather.

Understanding R-410A Pressures on a 95 Degree Day

To determine if your system is working optimally, it’s important to understand what pressures are normal under certain conditions.

The pressure of R-410A in your system is directly related to the temperature of the surrounding environment.

Higher temperatures outside typically lead to higher pressures inside the system. On a 95-degree day, you can expect certain pressure ranges on your system’s low and high sides.

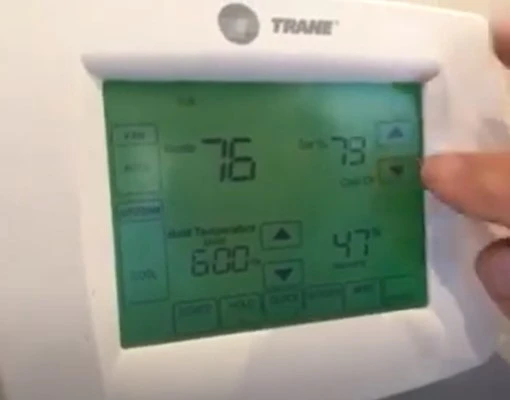

Normal Pressures for R-410A on a 95-Degree Day

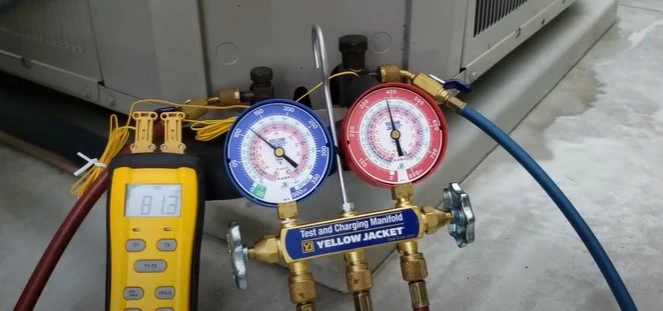

The pressure readings you get from your system can vary based on factors such as the specific design of the system, whether it’s under load, and other environmental conditions.

However, under typical circumstances, these are the expected pressure ranges for R-410A on a 95-degree day:

- Low Side Pressure: The low side pressure typically ranges between 120 to 140 psi.

- High Side Pressure: The high side pressure typically ranges between 300 to 350 psi.

These are standard readings you should see in a properly functioning system under typical operating conditions on a 95-degree day.

Factors That Affect R-410A Pressures

While the above numbers are typical, it’s important to remember that several factors can affect these pressures:

- System Load: A heavily loaded system (i.e., cooling a large area or during peak hours) will cause higher pressures.

- Evaporator Coils: Dirty or malfunctioning evaporator coils can lead to reduced cooling efficiency, causing pressure imbalances.

- Condenser Coils: If your system has dirty condenser coils, it can cause an increase in high-side pressure.

- Refrigerant Levels: Low refrigerant can cause lower-than-normal pressure readings, while overcharging the system can lead to higher-than-normal pressures.

It’s essential to consider these factors when analyzing pressure readings to determine if there’s an underlying issue with the system.

How to Troubleshoot R-410A Pressure Issues?

If your system is not showing the expected pressures, it could indicate a problem that needs to be addressed. Here are a few common troubleshooting tips to help you diagnose the issue.

1. Low Refrigerant Levels

Low refrigerant levels are one of the most common reasons for abnormal pressures in an HVAC system. When there isn’t enough refrigerant, the pressure on both the low and high sides will drop, causing the system to lose its ability to cool efficiently.

Symptoms of Low Refrigerant:

- The low side pressure will be below the expected range.

- The system will struggle to maintain temperature settings.

- The air coming out of the vents may be warm.

How to Fix It: If you suspect low refrigerant levels, you may need to recharge the system. However, it’s important to check for leaks before recharging, as the refrigerant will eventually leak out again.

2. Overcharged System

An overcharged system, where there’s too much refrigerant, can lead to dangerously high pressures. If your high-side pressure is higher than the normal range, it could indicate that your system is overcharged.

Symptoms of Overcharging:

- High-side pressures exceeding 350 psi.

- The system may trip off on high-pressure cutouts.

- Reduced cooling efficiency.

How to Fix It: If you find that the system is overcharged, you’ll need to release some of the refrigerant. This should only be done by a certified HVAC technician to ensure safety.

3. Dirty Coils or Blockages

Dirty evaporator and condenser coils can impede airflow and cause pressure imbalances. Blocked airflow reduces heat exchange efficiency, causing the pressures on both sides of the system to fluctuate.

Symptoms of Dirty Coils:

- High-side pressures are elevated.

- Low-side pressures are lower than expected.

- Poor cooling performance.

How to Fix It: Regular maintenance, such as cleaning the coils, can prevent this problem. If cleaning doesn’t resolve the issue, you may need to check for physical blockages.

4. Faulty Expansion Valve

The expansion valve controls the flow of refrigerant into the evaporator coils. If the valve is malfunctioning, it can result in incorrect pressure readings on both sides of the system.

Symptoms of a Faulty Expansion Valve:

- Low refrigerant flow.

- Inconsistent cooling performance.

- Abnormal pressure readings.

How to Fix It: A faulty expansion valve should be replaced by a professional HVAC technician to restore proper system function.

Best Practices for Maintaining Optimal Pressures

To ensure your HVAC system stays in top shape during hot weather, here are a few best practices for maintaining optimal pressures:

Regularly Check and Clean Coils

Make sure to inspect your evaporator and condenser coils at least once a year and clean them if necessary. Dirt and debris can accumulate quickly, leading to inefficient heat exchange and pressure problems.

Monitor Refrigerant Levels

Ensure your system is properly charged with refrigerant. If you suspect a leak or see a pressure drop, have a professional HVAC technician inspect the system for leaks and refill the refrigerant.

Conduct Routine Inspections

Schedule regular maintenance checks for your system, especially during the hottest months of the year. A certified technician can perform a full inspection and check the system’s pressure readings to catch any issues before they become serious.

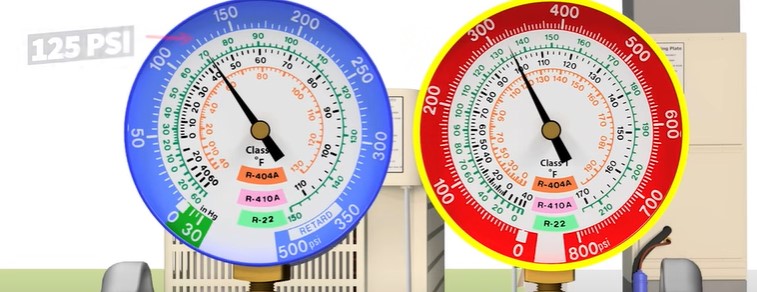

Use the Right Equipment

Always use the correct gauges and tools when checking refrigerant pressures. Incorrect gauges can give misleading readings, leading to faulty diagnoses and unnecessary repairs.

People also ask

What is the approximate pressure of a 410a AC unit on a 90 degree day?

On a 90-degree day, the approximate pressure for an R-410A AC unit would be:

Low Side Pressure: Around 120-140 psi

High Side Pressure: Around 280-300 psi

What are the perfect 410a pressures?

The perfect R-410A pressures for an AC system typically are:

Low Side Pressure: 120-140 psi

High Side Pressure: 280-350 psi

What should AC pressures be on a 90 degree day?

On a 90-degree day, the typical AC pressures for R-410A refrigerant should be:

Low Side Pressure: 120-140 psi

High Side Pressure: 280-300 psi

What should suction line temperature be 410a?

For an R-410A system, the suction line temperature should typically be around 40-55°F (4-13°C). This temperature can vary depending on the system’s load and environmental conditions, but it should generally be close to the evaporator temperature for optimal cooling performance.

Conclusion of 410A Pressures on a 95 Degree Day

In Conclusion, Understanding the typical 410A pressures on a 95 degree day is essential for maintaining a healthy HVAC system.

Proper refrigerant pressure ensures your system operates efficiently, providing reliable cooling in the hottest conditions.

By knowing what pressures to expect and how to troubleshoot common issues, you can keep your system running smoothly year-round.

Always follow maintenance best practices, and when in doubt, consult with an HVAC professional to address any pressure or performance concerns.